The Process

Eco-Luxe forms a circular, sustainable bridge between bespoke tailoring and traditional weaving techniques. Wool and cashmere waste from bespoke tailors is collected, sorted, and processed to preserve its quality. Using time-honoured methods, the fibres are blended with natural British yarn and woven into new fabric.

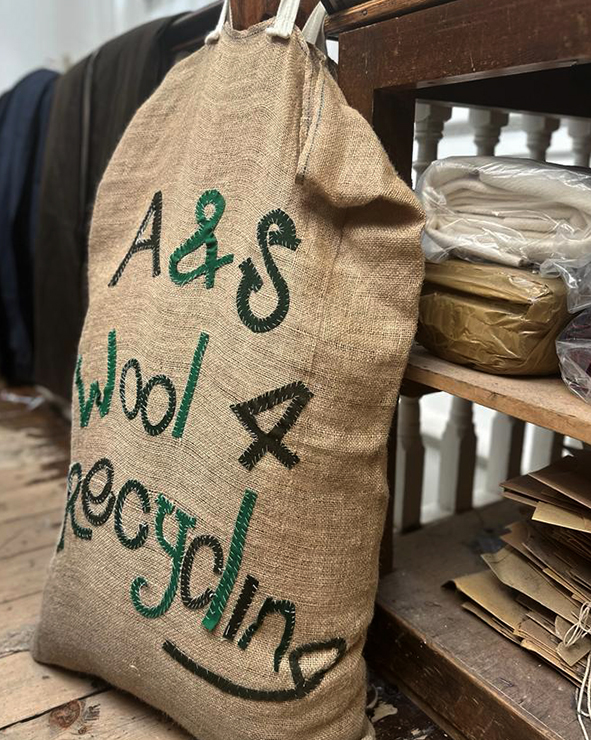

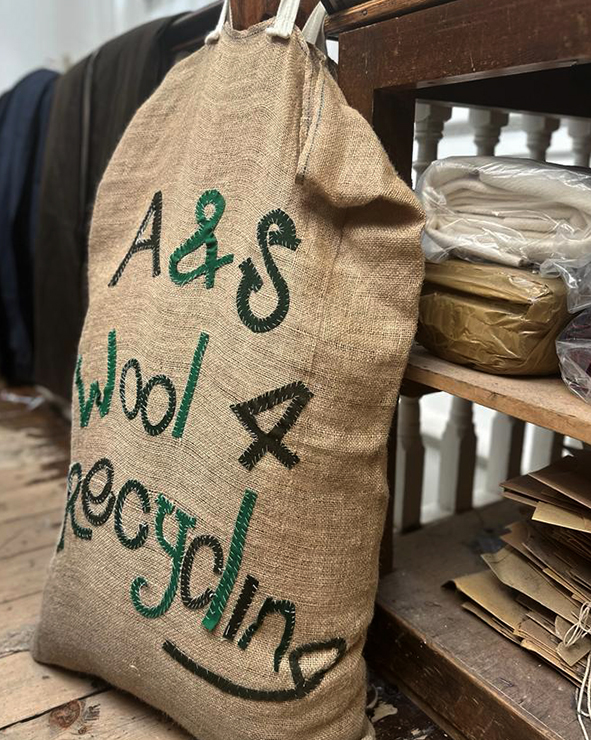

Collection of Waste Materials

Bespoke tailors and textile companies collect cuttings and waste material for repurposing into cloth.

Sorting & Removing Contaminates

To ensure the high quality of eco-luxe recycled fabrics, only pure wool and cashmere waste is used, with all contaminants like cotton threads and linings carefully removed.

Garnetting

Textile waste is broken down through a technique called garnetting. Specialist machines comb through the material opening the fibres into a fluffy, fibrous state. These fibres are shorter than the original raw material so they are blended with new British natural yarn to ensure a high-quality woven end product. Eco-Luxe is continually exploring ways to increase the proportion of recycled material in this blend while maintaining the highest levels of quality.

Carding

After blending, the fibers are carded to detangle and align them, ensuring a smoother spinning process.

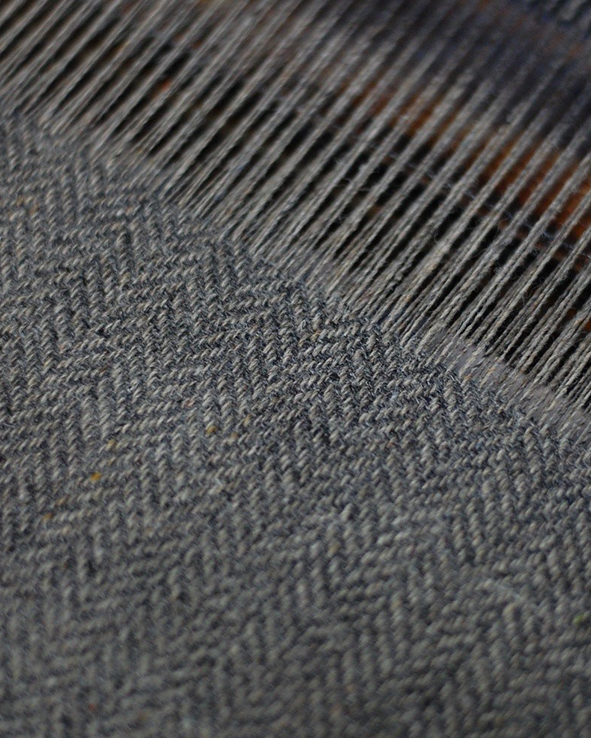

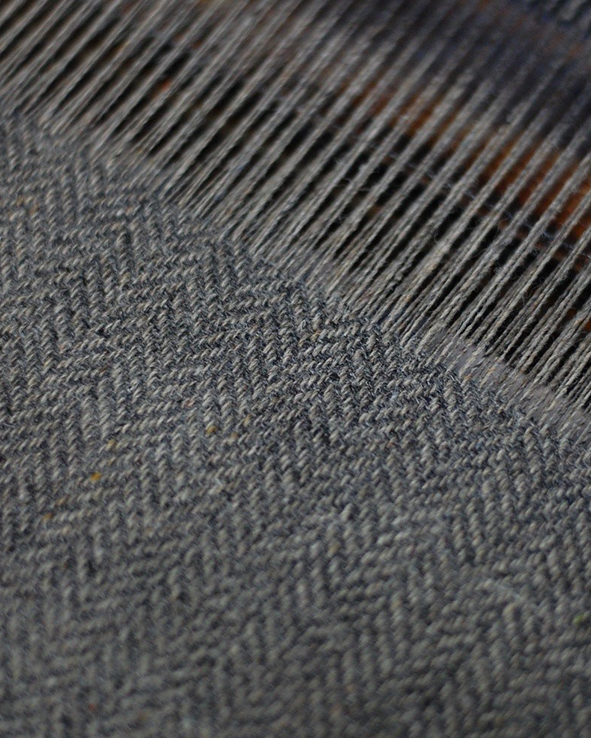

Weaving at Woven in the Bone

Albert Slippers in Eco-Luxe herringbone by Arthur Sleep.

Weaving

The repurposed yarns are woven into cloth using traditional methods and to Eco-Luxe creative designs.

Creating new products

Eco-Luxe fabrics are crafted to match the quality, feel and appearance of the original materials used in bespoke tailoring, making them indistinguishable from the original material collected by the tailoring companies.

Eco-luxe fabrics are commissioned and created to clients’ requirements or to Eco-Luxe designs and ensure that the traditional Yorkshire and British weaving and finishing methods and their exacting standard of processing are maintained for complete customer satisfaction. A limited eddition of stock supported designs are available by the metre.

Collection of Waste Materials

Bespoke tailors and textile companies collect cuttings and waste material for repurposing into cloth.

Sorting & Removing Contaminates

To ensure the high quality of eco-luxe recycled fabrics, only pure wool and cashmere waste is used, with all contaminants like cotton threads and linings carefully removed.

Garnetting

Textile waste is broken down through a technique called garnetting. Specialist machines comb through the material opening the fibres into a fluffy, fibrous state. These fibres are shorter than the original raw material so they are blended with new British natural yarn to ensure a high-quality woven end product. Eco-Luxe is continually exploring ways to increase the proportion of recycled material in this blend while maintaining the highest levels of quality.

Carding

After blending, the fibers are carded to detangle and align them, ensuring a smoother spinning process.

Weaving

The repurposed yarns are woven into cloth using traditional methods and to Eco-Luxe creative designs.

Creating new products

Eco-Luxe fabrics are crafted to match the quality, feel and appearance of the original materials used in bespoke tailoring, making them indistinguishable from the original material collected by the tailoring companies.

Eco-luxe fabrics are commissioned and created to clients’ requirements or to Eco-Luxe designs and ensure that the traditional Yorkshire and British weaving and finishing methods and their exacting standard of processing are maintained for complete customer satisfaction. A limited eddition of stock supported designs are available by the metre.

Albert Slippers in Eco-Luxe herringbone by Arthur Sleep.

Privacy Policy © Eco-Luxe 2025